NESHAP Halogenated Solvent Cleaning --- May 2007 Revisions

|

Background

On May 3, 2007, EPA published revised air emission standards for hazardous air pollutants from halogenated solvent cleaning operations that establish a facility-wide annual emissions limit of 60,000 kg/yr of methylene chloride (MC), perchloroethylene (PCE), and trichloroethylene (TCE), on a "risk-adjusted" basis. This was the first significant change in these rules since the National Emission Standard for Hazardous Air Pollutants (NESHAP) for solvent cleaning operations was published in 1994. The revisions mostly affect facilities with very big degreasers or a large number of smaller units. Aerospace and military depots are exempt from the new rule (due mainly to cost effectiveness and labor skill issues). All facilities, including the general finishing industry, aerospace facilities and military depots must continue to comply with the 1994 requirements.

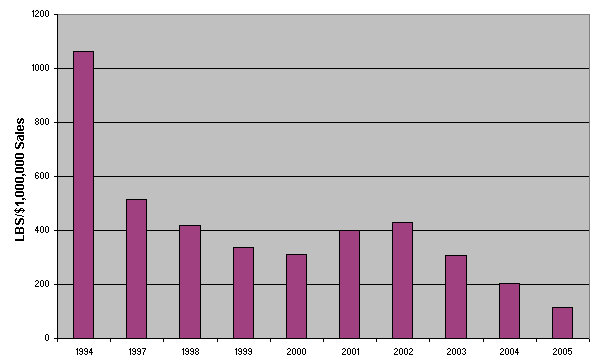

The 1994 NESHAP covers vapor degreasing (Figure 1) and immersion (cold) cleaning. Companies operating existing equipment, had until December 1997 (36 months) to comply with the requirements. Cleaning machines that began operations after November 29, 1993, (proposed regulation date) are required to comply with the standards immediately after startup. In developing the standards, EPA focused on equipment and work practices to achieve a level of control between 50 and 70 percent. In 1994, the use of halogenated solvent cleaning by the metal finishing industry was a common practice, although a declining use trend was already underway due mainly to scheduled phase-out of certain solvents (e.g., Montreal Protocol caused a production phase-out of TCA) and concerns over the NESHAP and possible future regulations. Once the 1994 NESHAP was in place, there was an immediate and major reduction in use of solvent cleaning over the next three years, followed by a less steep, but steady decline. Figure 2 shows data from the Metal Finishing Strategic Goals Program. These values are for quantities of solvent released to the air on a sales normalized basis. The SGP started collecting data in 1997, although most companies also submitted data for 1994, which served as a baseline. SGP data are still collected by the NMFRC, however there was insufficient data to look reliably past 2005. Today, solvent cleaning is still used by the aerospace industry, military depots, precision cleaning operations, and to a lesser extent by the general finishing industry. Most of these facilities use new solvents that are designed for environmental compliance. The cleaning/degreasing equipment has also changed significantly, it is often downsized and much more efficient and less polluting (e.g., totally enclosed systems, carbon adsorption capture devices).

Figure 2. Strategic Goals Program (SGP) Data -- Pounds of Toxic Organic Chemical Emissions per $1 Million Sales

Regulatory Revision

Under the 1994 NESHAP, companies are required to meet emissions standards for specific solvents and individual cleaning/degreasing machines. These rules are still in effect. Under the revised rule:

-

EPA has established a risk-adjusted value for MC, TCE and PCE solvents, based on their probability to cause cancer, and

-

emissions of these solvents from the total site must be below 60,000 lb/yr on a risk adjusted basis.

|

Enter the pounds per year usage at your facility:

|

The risk-adjustment factors for the three regulated solvents are:

-

methylene chloride (MC) = 1.0

-

trichloroethylene (TCE) = 4.25

perchloroethylene (PCE) = 12.5

| MC: 4,000 lb/yr x 1.0 = | 4,000 lb/yr |

| TCE: 4,000 lb/yr x 4.25 = | 17,000 lb/yr |

| PCE: 4,000 lb/yr x 12.5 = | 50,000 lb/yr |

| Total | 71,000 lb/yr There are no other additional equipment monitoring or work practice requirements associated with the facility-wide annual emissions limit. Annual emissions of PCE, TCE, and MC are determined based on records of the amounts and dates of the solvents added to cleaning machines during the year, the amounts and dates of solvents removed from cleaning machines during the year, and the amounts and dates of the solvents removed from cleaning machines in solid waste. Records of the calculation sheets showing how the annual emissions were determined must be maintained. More Resources 40 CFR Part 63 National Air Emission Standards for Hazardous Air Pollutants: Halogenated Solvent Cleaning; Final Rule, May 3, 2007. Full text of final rule. 40 PART 63 National Emission Standards For Hazardous Air Pollutants For Source Categories, Dec. 2, 1994. Full text of original regulation. Understanding Regulations on Solvent Cleaning Equipment -- What you Need To Know To Comply. Covers work practice changes and alternative cleaning methods. What's New | About PCRC | Compliance Assistance | Regulations | Technical Info | News | Homeowners | Search | Disclaimer | Home ©2012-2025 Paints and Coatings Resource Center |